Orifice flowmeter

- Tel:18019899982

- Fax:0550-7989666

- Mail:tkjd@tiankang.com

Description

The orifice flowmeter is a kind of orifice plate throttling device which adopts annular chamber pressure, and it is a differential pressure measuring device for measuring flow. A variety of differential pressure meters or differential pressure transmitters can be used to measure the flow of various fluids in the pipeline.Orifice flowmeters are widely used in petroleum, chemical, metallurgy, power, light industry and other sectors.

The measuring principle of orifice flowmeter is:

The fluid filled with pipes, when they flow through the throttle device in the pipeline, will form partial contraction at the throttle parts of the throttle device, so that the flow rate increases and the static pressure is low. So the pressure drop is generated before and after the throttle parts, that is, the pressure difference. The greater the flow rate of the medium flow, the greater the pressure difference before and after the throttling parts, so the orifice flowmeter can measure the pressure difference. To measure the size of fluid flow. This measure is based on the law of conservation of energy and the law of continuity of flow.

The integrated orifice flowmeter is a new generation flowmeter, which integrates the functions of flow, temperature and pressure detection, and can automatically compensate temperature and pressure. The annular chamber plate adopts advanced microcomputer technology and micro power consumption technology, with strong functions, compact structure, simple operation and convenient operation.

Two. The characteristics of ZY-LG orifice flowmeter are:

The throttle device of the 1. orifice flowmeter is easy to reproduce, simple, strong, stable and reliable in performance, long in service life and low in price.

2. hole plate calculation adopts international standards and processing.

The 3. orifice flowmeter has a wide range of applications. All single-phase flows can be measured, and some miscible flows can also be applied.

4. standard type throttle device can be used without real flow calibration.

5. the single hole orifice flowmeter is easier to install, no pressure tube is needed, and it can directly connect differential pressure transmitter and pressure transmitter.

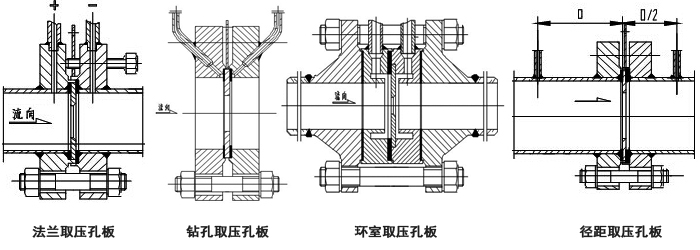

Three, the orifice flowmeter's pressure way:

1, annular chamber pressure standard orifice plate:

It is a standard orifice. Due to the realization of ring chamber pressure, the accuracy of measurement is improved, and the length of small straight pipe segments needed for installation is shortened, which can be widely applied in various departments.

2, angle separate drilling standard pressure orifice plate:

It is a standard orifice. When the diameter of the pipe is above 400 millimeters, this form is adopted. The way of pressure is flange drilling, pressure equalizing, circular equalizing ring or square equalizing ring. The orifice plate can be a hole with or without a standard hole.

3. Flange pressure standard orifice plate:

It is a standard orifice. Regardless of the diameter of the pipe, the center of the pressure holes on the upstream and downstream ports are all located at 1 times (25.5mm) from each end of the orifice plate, and the oil refining system generally adopts this form.

4. Standard orifice plate with diameter spacing.

It is a standard orifice. The pressure is taken for the pipe. The upper pressure hole center is located at the inner diameter of the pipe at the front of the orifice plate.The center of the downstream pressure hole is located at the end of the hole plate and is half the inner diameter of the pipe.

5. Orifice plate:

It is a non-standard orifice. It is used for measuring the fluid in 10 millimeter to 50 millimeter diameter.

6, double orifice plate:

It is made up of two standard orifices installed in a straight pipe way at a certain distance. According to the direction of the flow beam, the front hole is called the auxiliary orifice plate, and the rear orifice is called the main orifice plate. The section ratio M1 of the auxiliary orifice plate is larger than that of the main orifice plate m. The two orifice forms a nozzle similar to the liquid wall. It is used for low Reynolds number fluid or high viscosity flow measurement.

7. Round holes:

It is a non-standard orifice, which is suitable for measuring the flow of dirty, bubble or solid particles. The measurement accuracy is low.

8. Conical inlet orifice plate:

It is a non-standard orifice. The angle between the circular cone and the centerline is 45 degrees. The cone inlet orifice plate can be applied to the occasions where the Reynolds number is very low, but the pipe size should not be less than 25 mm.

Four. The length of the short straight pipe on the upstream and downstream side of the throttling part is:

straight path than Beta excess | Upstream blocker parts and length of short straight pipe section of throttling parts | Upstream short straight Length of pipe section (package) It is included in this table. Choke parts | ||||||

A single 90 degree elbow or three way (fluid flows out of only one branch). | Two or more 90 bend elbows on the same plane. | Two or more 90 bend elbows on different planes. | Gradually decreasing tube (from 2D to D in length from 1.5D to 3D) | Gradually expand tube (from 0.5D to D in length from 1D to 2D). | Ball valve Full open

| Full bore ball valve or gate valve fully open. | ||

Zero point two zero Zero point two five Zero point three zero Zero point three five Zero Point Four Zero Zero point four five Zero point five zero Zero point five five Zero point six zero Zero point six five Zero point seven zero Zero point seven five Zero point eight zero | 10 (6) 10 (6) 10 (6) 12 (6) 14 (7) 14 (7) 14 (7) 16 (8) 18 (9) 22 (11) 18 (14) 36 (18) 46 (23) | 14 (7) 14 (7) 16 (8) 18 (9) 18 (9) 20 (10) 22 (11) 26 (13) 18 (14) 32 (16) 36 (18) 42 (21) 50 (25) | 34 (17) 34 (17) 34 (17) 36 (18) 36 (18) 38 (19) 40 (20) 44 (22) 48 (24) 54 (27) 62 (31) 70 (35) 80 (40) | Five Five Five Five Five Five 6 (5) 8 (5) 9 (5) 11 (6) 14 (7) 22 (11) 30 (15) | 16 (8) 16 (8) 16 (8) 16 (8) 16 (8) 17 (9) 18 (9) 20 (10) 22 (11) 25 (13) 30 (15) 38 (19) 54 (27) | 18 (9) 18 (9) 18 (9) 18 (9) 20 (10) 20 (10) 22 (22) 24 (12) 26 (13) 28 (14) 32 (16) 36 (18) 44 (22) | 12 (6) 12 (6) 12 (6) 12 (6) 12 (6) 12 (12) 12 (12) (()) (()) (()) 16 (8) 20 (10) 24 (12) 30 (15) | 4 (2) 4 (2) 5 (2.5) 5 (2.5) 6 (3) 6 (3) 6 (3) 6 (3) 7 (3.5) 7 (3.5) 7 (3.5) 8 (4) 8 (4 |